QB Series Peripheral Type Water Pump

Application

suitable for pumping clean water,such as supply water from wells,pools etc. It is also suitable for water pressure boosting,gardening and automatic water supplying system if composed with other appliances.

in particular the automatic distribution of water from surge tanks,watering gardens and for boosting insufficient water pressure.

These pumps should be installed in a covered area,protected against the weather.

Working conditions

Max temperature of Fluid up to +80℃

Max Pressure 10bar

Max Ambient Temperature up to 40℃

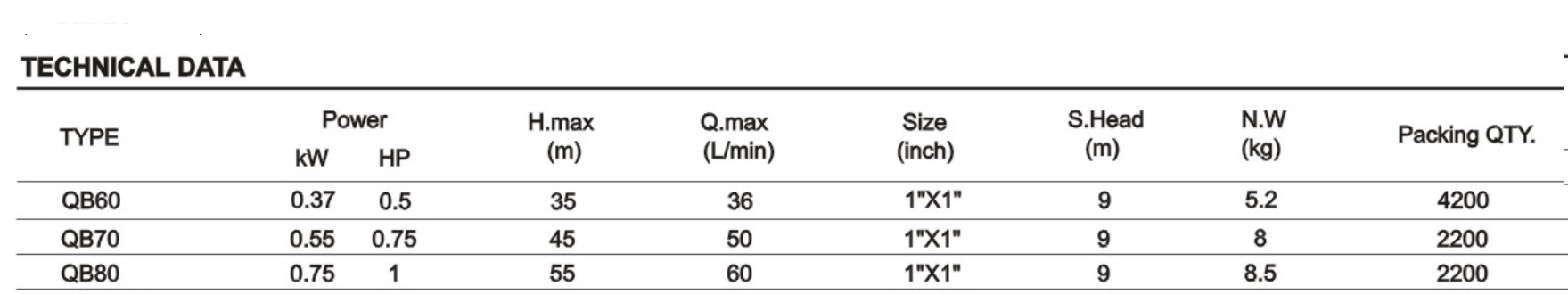

Technical data

Technical Description

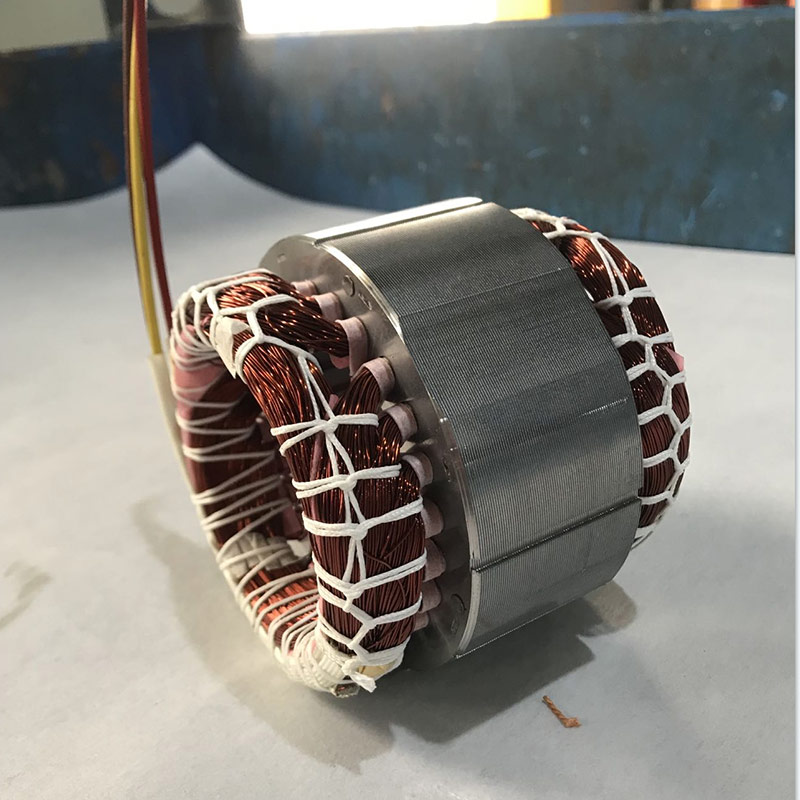

1. motor

100% full copper wire, machine wiring,new material stator,low temperature rise,stable working

(aluminum wire and different stator length made as you require)

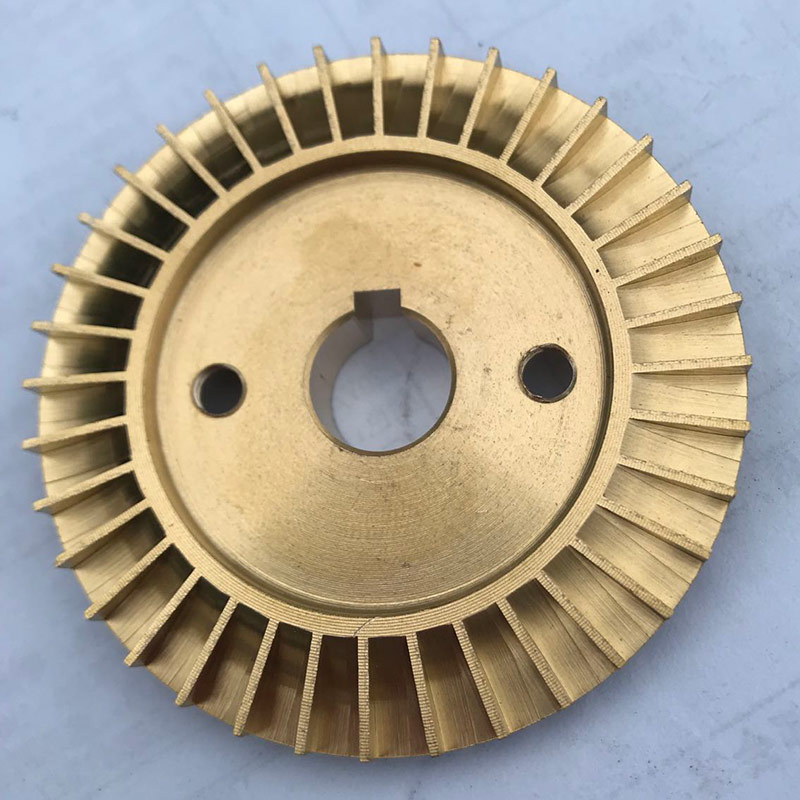

2. Impeller

Brass material as standard

Stainless steel material for choice

Aluminum material for choice

Plastic material for choice

3. Rotor and shaft

Surface moisture proof ,anti rust treatment

Carbon steel shaft or 304 stainless steel shaft

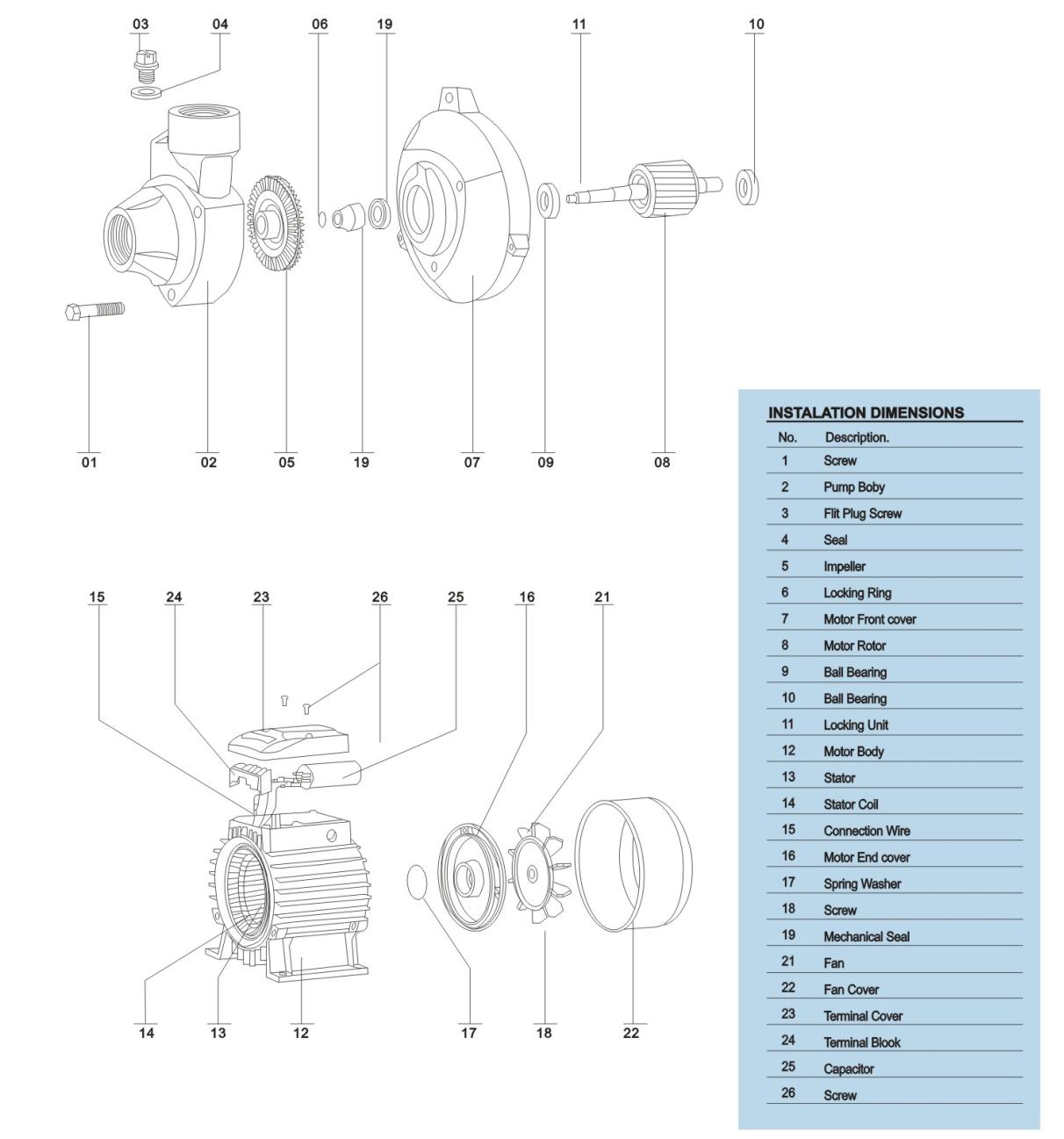

Exploded View

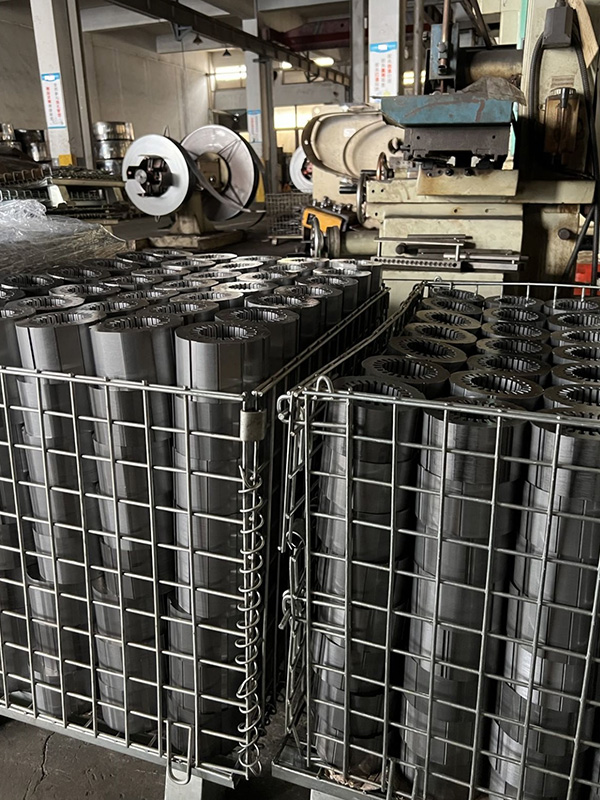

Production line

Quality control

Follow ISO9001 quality management system.

Design at the beginning with testing and checking before acceptance,from sample to batch purchase.

Material examination for our suppliers before getting into our warehouse.

To make quality control plan ,and preparation of operation instructions.

Detected by test equipment during production,Spot check again before shipment.

Installation instruction

The pumps must be installed in a drywell-ventilated place with an ambient temperature of no more than 40℃(Fig.A).Fix the pump in place on a solid flat surface using suitable bolts to avoid vibration. The pump must be installed in a horizontal position toensLi that the bearings operate correctly.The diameter of the intake pipe must not be smaller than that of the intake mobth. If the intake height exceeds 4 metres, use a pipe with a larger diameter.The diameter of the deliverypipe must be chosen to suit the flow rate and pressure required at the takeoff points.The intake pipe must beslightly angled up towards the intake mouth to avoid the formation of air locks(Fig.B).Make sure that the intake pipe is completely airtight and immersed in the water by at least half a metre to avoid the formation of vortexes. Always fit a foot valve at the end of the intake pipe. It is advisable to fit a non-return valve between the delivery mouth and flow rate adjustment gate valve to avoid dangerous water hammering in the event of the pump suddenly stopping. This measure is compulsory if the delivery water column is over 20 metres.

The pipes mustalways be fitted us ing the re lated brackats (Fig. C)to avoid transmitting stress to the pump body. Take care not to damage any part by overtightening the pipes when fitting them.

Packing

Design Color inner carton box with foam packing ,with master box or not

About 4000pcs fit for whole 20” container.

Transportation

Loading container to Ningbo port as ship departure port.

Other ways are also ok,such as Shanghai port, Yiwu and so on

Samples

Make Free sample for your testing,ask for some charge if too many samples ,and discuss for charge return if you make formal order later.

Send the sample by land,sea,even air transport as you prefer.

Payment term

T/T term: 20% advance deposit,80%balance against copy of bill of lading

L/C term: normally L/C at sight, longer time for discuss.

D/P term, 20% advance deposit, 80% balance by D/P at sight

Credit insurance: 20% advance deposit,80% balance OA 60days after insurance company give us report, longer time for discuss

Warranty

The product warranty period is 13 months (calculated from the date of bill of lading). According to the relevant vulnerable parts and components, if there is a manufacturing quality problem belonging to Supplier during the warranty period, Supplier shall be responsible for providing or replacing the repair parts after the joint identification and confirmation of both parties. The quotation of conventional products does not include any proportion of accessories. During the warranty period, according to the actual feedback, we will negotiate to provide vulnerable parts for maintenance, and some parts may need to be purchased with compensation. Any quality problems can be reported for research and negotiation.