IDB Series Peripheral Type Water Pump

Application

appropriate for pumping clean water, such as for filling pools and wells. If combined with other appliances, it is also excellent for increasing water pressure, gardening, and automatic water supply systems.

especially for watering gardens, automatically distributing water from surge tanks, and increasing low water pressure.

These pumps ought to be set up in a covered area that is weatherproof.

Working conditions

Max temperature of Fluid up to +60℃

Max Pressure 10bar

Max Ambient Temperature up to 40℃

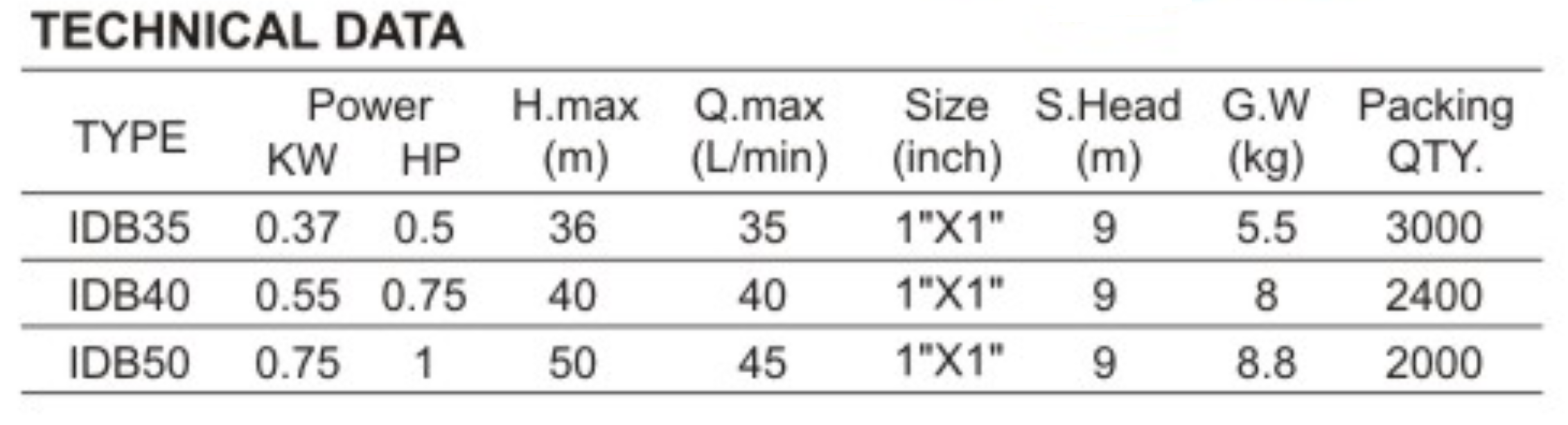

Technical data

Technical Description

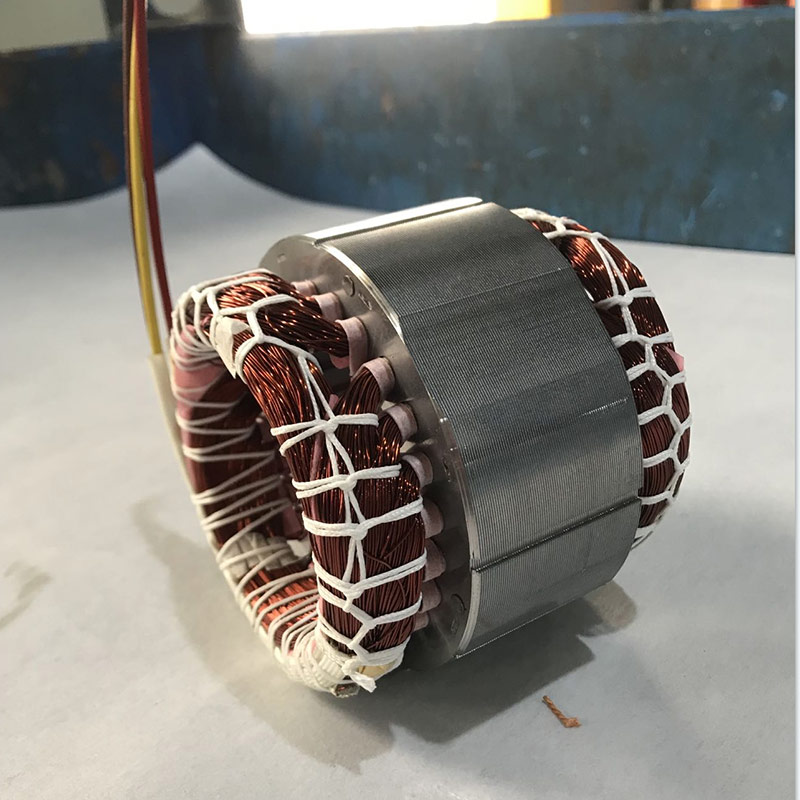

1. motor

100% copper winding coil, machine wiring,new material stator,low temperature rise,stable working

(aluminum winding coil for your choice available,different stator length for your choice also)

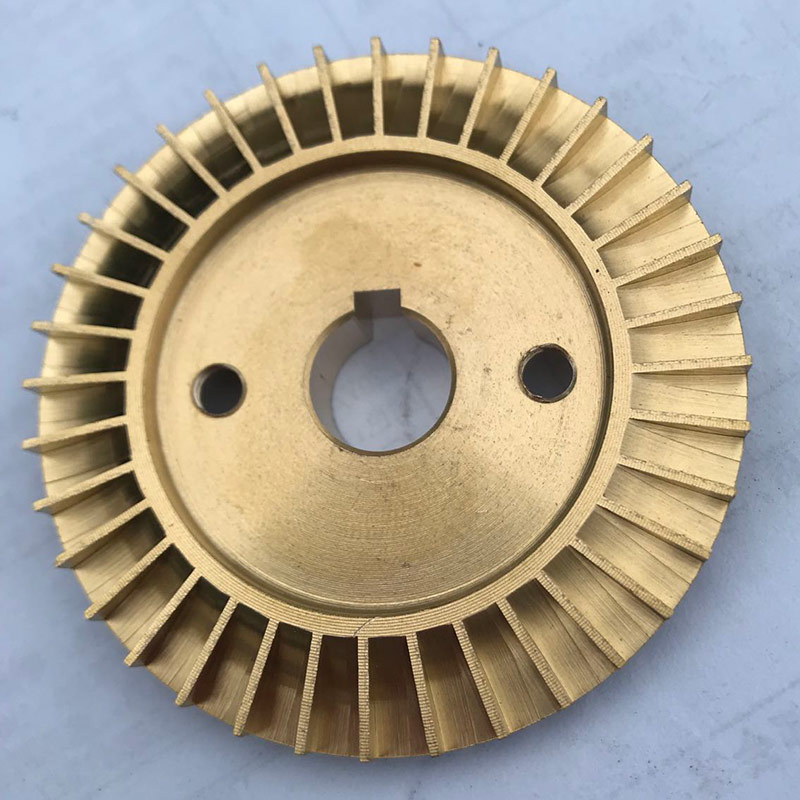

2. Impeller

Brass material

Stainless steel material

Aluminum material

Plastic material

3. Rotor and shaft

Surface moisture proof ,anti rust treatment

Carbon steel shaft or 304 stainless steel shaft

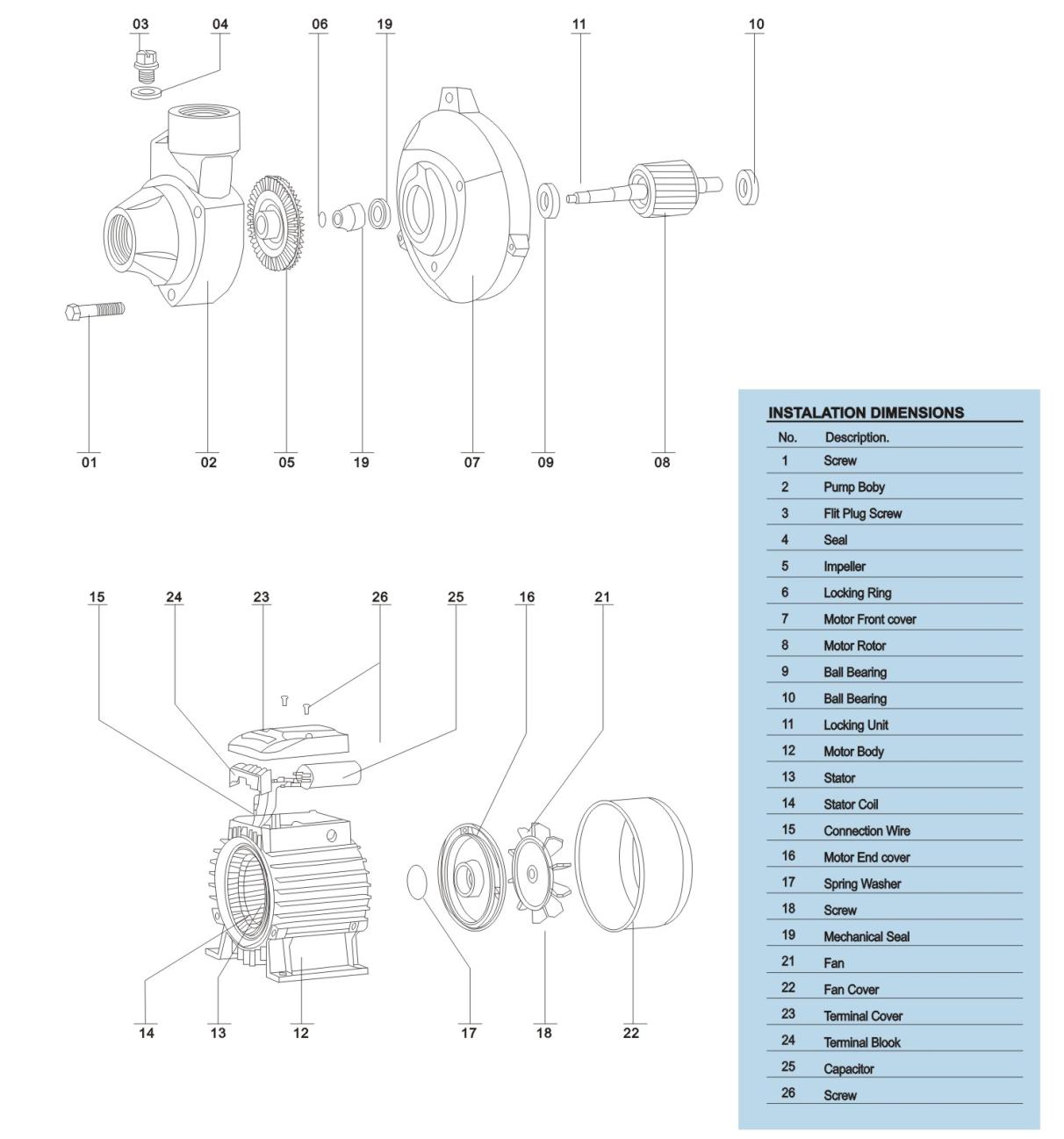

Exploded View

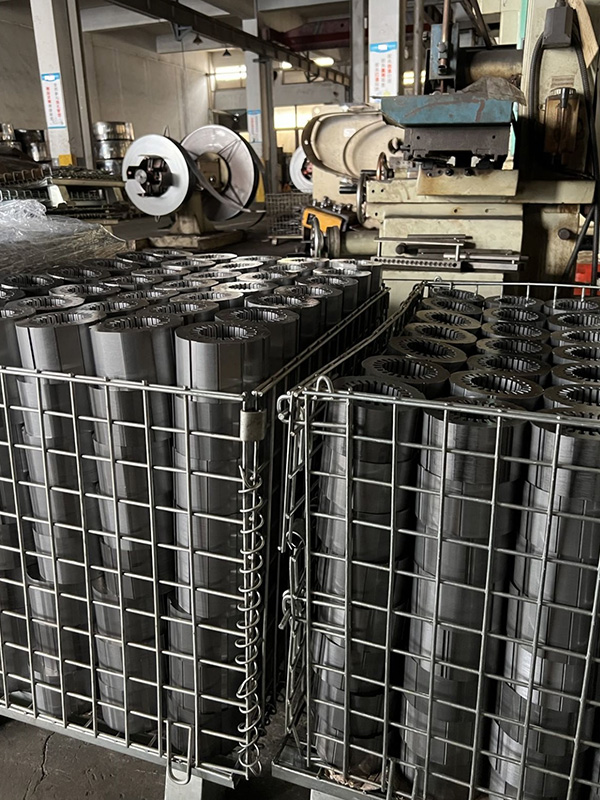

Production line

Quality control

observe the quality management system ISO 9001.

Starting with design, testing, and approval before acceptance, from a sample to a batch purchase

Before entering our warehouse, our suppliers' materials are examined.

to prepare operation instructions and a quality control strategy.

Test equipment detected it during production; a second spot check was done before distribution.

Installation instruction

The location of the pumps must be drywell-ventilated and have an ambient temperature of no more than 40°C (Fig.A). To prevent vibration, secure the pump using the proper bolts on a stable, flat surface. To ensure that the bearings function properly, the pump must be mounted horizontally. The intake pipe's diameter cannot be less than the intake motor's. Use a pipe with a bigger diameter if the intake height is greater than 4 meters. The deliverypipe's diameter must be selected to match the flow rate and pressure necessary at the takeoff sites. To prevent the development of air locks, the intake pipe must be slightly inclined up toward the intake mouth (Fig.B).To prevent the creation of vortexes, make sure the intake pipe is entirely airtight and submerged in the water by at least half a meter. Always install a foot valve at the intake pipe's terminus. In order to prevent potentially harmful water hammering in the event of a sudden pump stop, it is recommended to install a non-return valve between the delivery mouth and flow rate adjustment gate valve. If the delivery water column is greater than 20 meters, this precaution is required.

To prevent tension from being transferred to the pump body, the pipes must always be installed using the reinforced brackets (Fig. C). When installing the pipes, take care not to overtighten any component.

Packing

Independent Color inner carton box,6 in 1 master carton box packed.

Transportation

Loading whole container or bulk shipment

Priority in Ningbo port, or yiwu,Shanghai,and other methods.

Samples

Free sample or some charge for samples if expensive,discuss for charge return if you make formal order.

Could check land,sea,even air transport for sample as you prefer.

Payment term

T/T term: 20% advance deposit,80%balance against copy of bill of lading

L/C term: normally L/C at sight, longer time for discuss.

D/P term, 20% advance deposit, 80% balance by D/P at sight

Credit insurance: 20% advance deposit,80% balance OA 60days after insurance company give us report, longer time for discuss

Warranty

The warranty period for the product is 13 months (calculated from the date of bill of lading). If there is a manufacturing quality issue that belongs to the supplier during the warranty period, according to the pertinent vulnerable parts and components, the supplier must be liable for delivering or replacing the repair parts following the joint identification and certification of both parties. There is no mention of accessories in the quotation for conventional goods. According to the real feedback, we will negotiate to offer vulnerable components for maintenance throughout the warranty term, and some parts may need to be purchased for a cost. You can submit any quality issues for investigation and negotiation.